Universal Holding Fixtures

Universal holding fixtures do not hold the workpiece over its entire surface, but typically use round vacuum suction cups. These suction cups adapt actively or passively to the local curvature of the component. In addition, each individual suction cup is raised to the corresponding height by an actuator, at least in one dimension. This also replicates the surface of the part to be held, but only at typical grid intervals of 200 mm to 500 mm. A fixture of this type can be used for a family of parts and is therefore called “universal.”

Advantages of our Holding Fixtures

Active and passive solutions

Tailor-made table size and actuator positions

Sealed for wet machining

High stiffness for drilling and milling

Stroke lengths up to 2 m

Accuracy up to 0.1 mm

Multi-end-effector capabilities

Swivelling suction cups

Low maintenance due to high-quality components

Fast and simple actuator replacement

Active vs. Passive

Depending on the specific requirements and the underlying production process, a choice is made between active and passive universal clamping devices:

ACTIVE

fast and flexible

actuators with servo drive

BECKHOFF control with HMI

-

All actuators move synchronously, minimizing setup time

-

Retraction during milling to prevent collisions with the milling head

-

Use of actuators to actively pull or press the component into the desired shape

Comparison of conventional vs. universal

Comparison of conventional vs. universal

Schnell und flexibel | Aktuatoren mit Servo-Antrieb | BECKHOFF Steuerung mit HMI

-

Alle Aktuatoren fahren synchron und minimieren somit die Setup Zeit

-

Retracts während der Fräsbearbeitung zur Verhinderung von Kollisionen mit dem Fräskopf sind möglich

-

Verwendung der Aktuatoren um das Bauteil aktiv in die gewünschte Form zu ziehen oder drücken

-

Kosteneffizient und robust | Aktuatoren sind pneumatisch angetrieben | Steuerung mittels CNC-Maschine

-

Die Aktuatoren fahren sequentiell, da die Fräsmaschine die Endlage als Stopper definiert

-

Direkte Einbindung in die CNC Maschine ohne eigene Steuerung möglich

-

Kosteneffiziente Lösung

-

Sehr robust und zuverlässig auch in Umgebungen mit viel Wasser

-

Sehr hohe Genauigkeit

-

- Error: empty slot

- Error: empty slot

- Error: empty slot

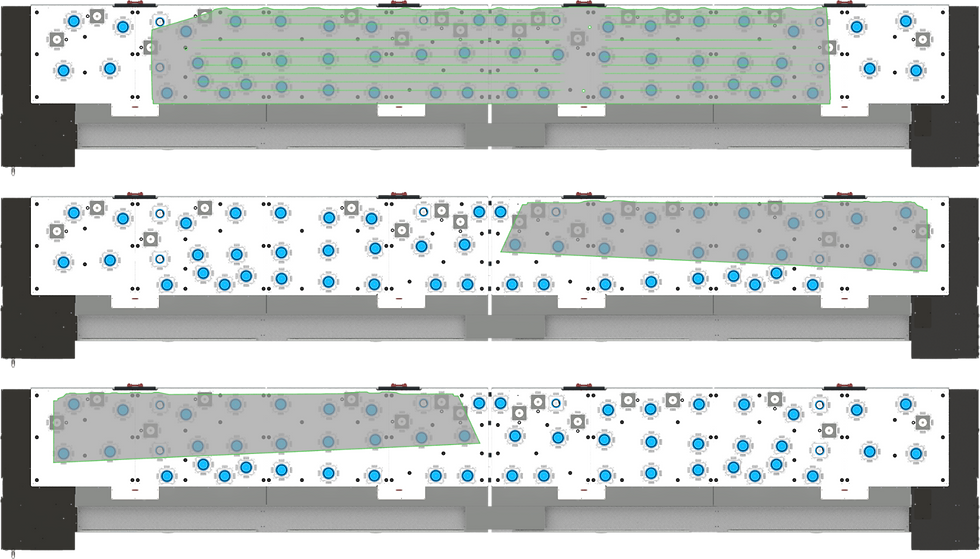

Individual Actuator Positions

If the parts are known at the start of the project, the actuators can be perfectly adapted to their shape and requirements.

The result: fewer suction cups, maximum holding quality, and precise, collision-free positioning near the milling tool.

The high flexibility of the system enables even simple grid positions to be implemented quickly and efficiently.

Various End Effectors

In addition to round suction cups, an individual hard tool can be mounted at any position. This makes component positioning very easy and provides improved support in monolithic areas to prevent vibration.

MICADO VACUUM SUCTION CUP

freely movable in various sizes

HARD TOOL

for flat support and component alignment

MICADO VAKUUMSAUGER

freely movable in various sizes

HARD TOOL

for surface support and component alignment